Swissmem sees digitalisation as industry saviour

Swiss electrical engineers, machine builders and fine tools makers have high hopes that efficiencies brought in by the digitalisation of production lines will prove the perfect antidote to the pressures of the strong franc.

But an employees’ lobby group has urged companies to bring in guidelines to ensure that workers also benefit from modern technologies, rather than be left behind and jobless during the so-called fourth industrial revolution – or industry 4.0.

Swissmem, the umbrella group for more than 1,000 companies, has painted a grim picture facing many of its member firms – most of them small and medium sized enterprises (SMEs) and exporters to the eurozone. Last year proved a difficult one after the Swiss National Bank (SNB) ended the euro-franc exchange rate cap.

Since then, the value of the franc has soared against many currencies, particularly the euro. A survey of member firms found that orders had fallen 14% in 2015 and sales had dropped 7%. “Even more dramatic was the deterioration in margins, which plunged many businesses into the red,” Swissmem stated in its “Annus Horriblis” report on Monday.

“However, if exchange rates and business trends do not worsen any further, a recovery in the MEM industries is likely in the medium term,” the statement added. “Industry digitization is a particular source of new growth opportunities.”

Lost workers

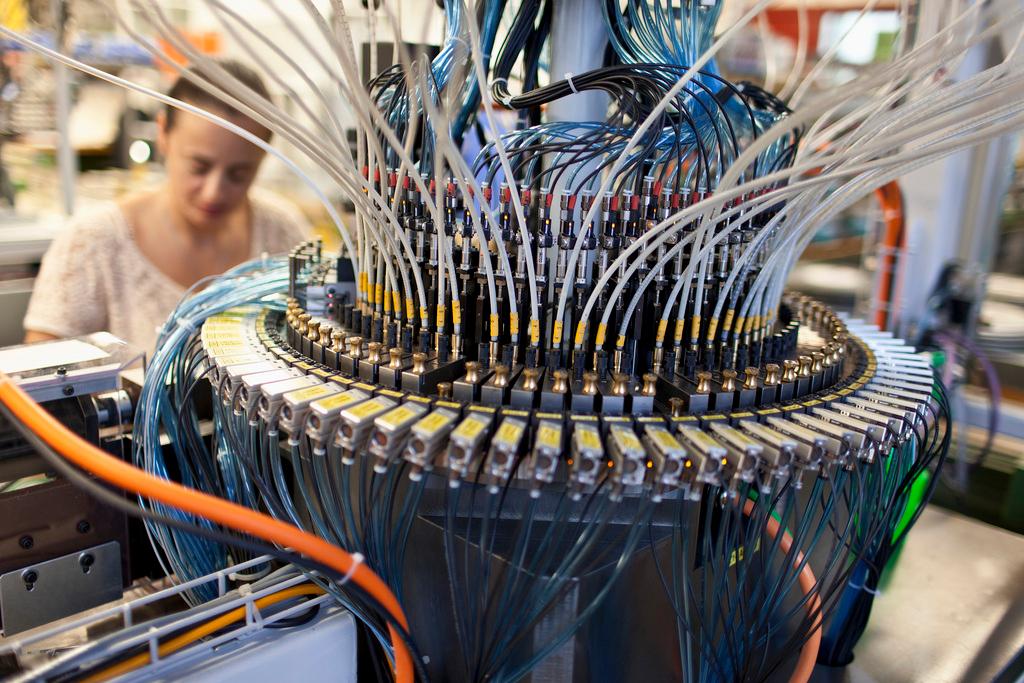

The Swiss Employees’ Association jumped on the Swissmem findings, calling for its companies to establish a clear set of guidelines for protecting workers during the transformation. Digitalisation is seen by many as a double-edged sword: improving production line efficiency with smart robots and intelligent software systems, which could potentially replace people.

Several economic surveys have predicted that around half of all current job positions could disappear as a result of digitalisation. And it is less clear whether all of these jobs will be made up for with the creation of new positions, such as robot builders or software engineers.

The Employees’ Association is therefore demanding that workers are taken into account. It wants firms to invest in re-training its workforce and to take full advantage of government programmes that promote innovation.

The lobby group points out that staff have shown loyalty and flexibility by accepting shortened working weeks, or alternately worked longer hours for no extra pay, during the worst months of volatility last year. Some 150,000 manufacturing jobs have been lost in the last 15 years, and yet the sector still contributes the same share to the country’s economic output (20% of total gross domestic product GDP), the organisation said.

A continuation of that trend would result in an “inexorable backlash”, the Employees’ Association stated. “Namely, that industry 4.0 will lose its much needed workforce.”

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.