It’s boom time for the ‘Davos sledge’

The small wooden sledges were originally intended for transporting goods until a carpenter launched the “Davos sports sledge”. The museum-piece mode of transport has since been a fundamental part of Swiss wintertime and carpenters like Paul Burri are keeping the tradition alive.

It gets quite cramped in Paul Burri’s small carpentry workshop in Lohnstorf, canton Bern, at the start of winter. Everything is geared towards one thing – sledges. Sawn wooden parts lie ready in one corner. In another, finished sledges are stacked almost up to the ceiling. Outside, the little street where Burri works and lives is covered in snow. It is the same little street that Burri raced down on a sledge with his brothers during his childhood. The local authority’s road patrol used to spray gravel on the hardened snow to make the surface safe. But the Burri boys made themselves a plough to get rid of the speed-curbing grit and carried on sledging. Now, over 50 years later, Burri is the local sledge-maker.

It is not just Burri who has childhood memories of sledging. At the first sign of snow, Swiss children slide or tumble down the nearest suitable hill on their wooden toboggans accompanied by parents or grandparents who did exactly the same thing in their day. These sledges are often the “Davos” model. This archetypal Swiss wooden sledge has not changed over the generations.

The 80 to 130-centimetre-long wooden sledge with the engraved inscription “Davos” is a Swiss classic. Its name dates back to the first historic sledge race of 1883 in Davos which also led to the foundation of the British-dominated “Davos Toboggan Club”. Davos wainwrights made the first sledges for tourists before that. In 1888, Tobias Branger, a pioneer of skiing, unveiled his Davos sports sledge, creating the original prototype of the Davos model which is still used today.

Ash is mandatory

The omnipresence of this sledge is down to Burri and a dozen or so other firms across the country. They are continuing the craft of sledge-making and know exactly what makes a good sledge. It must be made of ash. This wood is hard, tough, long-stranded and elastic. This means the sledge’s runners bend well and the seat slats give without breaking.

Burri is a carpenter, but every sledge-maker is also a bit of a chef. A saucepan is used in the production of the sledge’s runners which are bent upwards. At least Burri makes it sound like what goes on in a kitchen: “The wooden parts used for the runners are cooked for an hour in wet steam at 150 degrees celsius.”

The parts are then bent and attached. When they have cooled down and dried out again, the curve remains in place. However, no one piece of wood is exactly the same as the next. This means that every curve – and each sledge – is slightly different.

Original regional variants

The straight-line Davos model is regarded as the original wooden sledge. In addition, there are a host of original regional variants as many mountain regions produced their own typical sledges during the 19th century. As well as the Davos sledge, the Grindelwald model is still commonplace while the Bergün, Goldiwil and Grönland (from Alp Grön in the Justistal valley) models are also well-known.

Year after year, Burri provides evidence that nothing changes in the world of traditional sledges. Or does it? What about all the smooth frames made of plastic or the ultra-modern, steerable and rapid sports sledges known as luges? “The original is doing fine,” says Burri. He is aware of the modern trends and even builds a “sportier model” himself. The tried-and-tested model still gives him the most pleasure though. He has nevertheless accepted one of the obvious changes. Originally the sledge’s main use was to transport small loads through snow-covered villages. Today, it is used for recreational purposes.

The modernists on the sledging scene shake their heads in disbelief at the sheer number of basic Davos sledges and similar models still being crafted by hand. They look on sledgers using the hard-to-steer Davos model as die-hards stuck in the past. One thing is certainly true. Users of traditional wooden sledges rarely get an adrenaline rush. Yet travelling over the white winter wonderland with the spray of snow in your face can provide a true sense of happiness. Sledge-maker Burri believes the power of this tradition contributes to its lasting success. Children have also grown up with basic sledges and not sophisticated racing machines. The drawback of the Davos sledge also works in its favour: “The fact that it doesn’t go so fast means it’s less dangerous.”

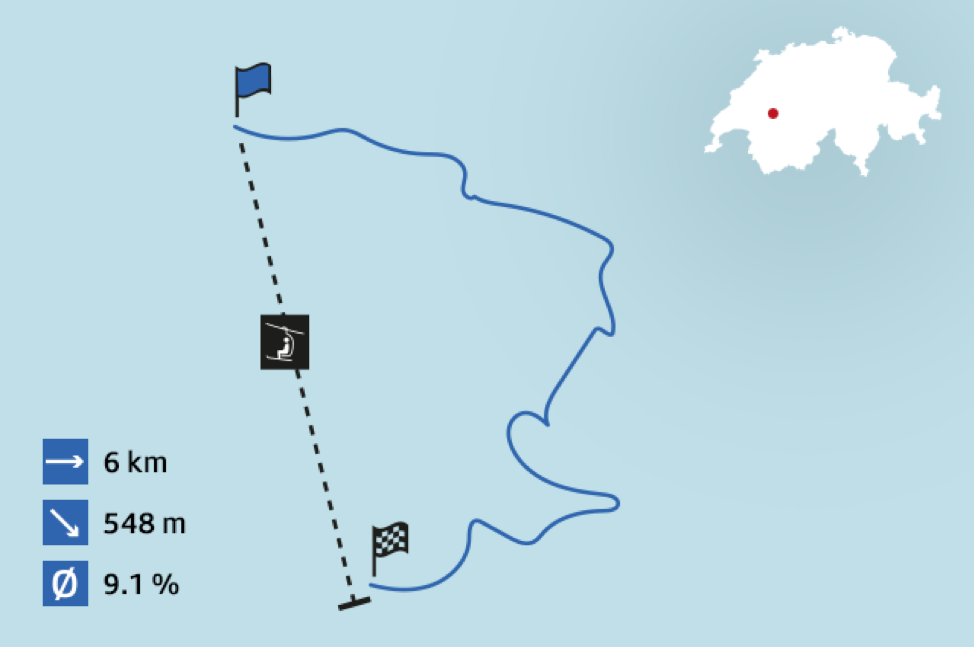

In Switzerland, almost two million people use sledge runs in winter, choosing one of over 120 prepared tracks running for kilometres. The number of these commercial runs is on the rise, and are ever more impressive. The longest sledge run in the world, at 15 kilometres, has a view of the Eiger, Mönch and Jungfrau mountains and goes from Faulhorn through Bussalp to Grindelwald. It goes without saying that commercial providers have long since discovered and ensnared the seemingly anachronistic sledgers.

More

How to make it down a sledge route in one piece

But sledging is also booming beyond the runs on practically all snow-covered hills that are steep enough. Has Paul Burri noticed this boom? He makes an average of 200 to 300 sledges each year. However, this winter the figure stands at over 1,000. He modestly puts this down to “good fortune” as a single large order has driven numbers up. But the other sledge-makers across the country are not complaining either. As well as traditionalists like Burri, some firms are launching an exclusive small-scale series production of luxury sledges with brass fittings. The “made in Davos” model is also experiencing a boom. Sledge-making there had ground to a halt in 1954. But a native of Arosa, Paul Ardüser, has now entered the market again. Switzerland’s biggest manufacturer, 3R AG in Sulgen, sells up to 5,000 sledges of all kinds each season. Erwin Dreier, the chief executive of 3R, does not believe the Davos sledge will be squeezed out of the market: “It’s ultimately part of Swiss heritage,” he says.

Burri works with the pride of a craftsman who knows that he can make a sledge “entirely on his own”. He carefully saws the bowed wooden parts which have now dried out again into two halves to produce two identically curved runners. He selects attractive wood for the frame of the sledge placed between the runners and the seat. He cuts the slats to length with a good eye. He bends the steel guides with a steady hand and screws them onto the wooden runners. One sledge after another is produced in this way. The pile of sledges in the little workshop continues to grow. Standing by this pile, Burri remarks: “There’ll always be sledges.”

The sledges have also rubbed off on the man who creates them. Burri favours an old-fashioned way of doing things. Does he sell his top-notch products online? Not a chance. Can people order sledges from him by email? No, they cannot. People know where he is: “They can find me here in Lohnstorf.” Customers have to knock on the door of the small carpentry workshop in the little street which Burri used to slide down as a child.

This article was first published in the Swiss ReviewExternal link by the Organisation of Swiss Abroad (OSA). The official magazine for Swiss Abroad is published six times a year in four languages – on paper, on the Internet and as an app.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.