‘Artificial tree’ from Switzerland to produce green hydrogen

A unique solar reactor promises to overcome the high costs and transport difficulties involved in developing green hydrogen. The first pilot plant will go into operation in Switzerland in February 2024, but the innovation is also attracting interest abroad.

The parabolic dish installed on the campus of the Swiss Federal Institute of Technology Lausanne (EPFL) does not go unnoticed. With a diameter of seven metres and pointed towards the sky, it looks like a telescope. However, it is designed not to receive radio waves from space but to use sunlight and water to produce hydrogen and oxygen.

It’s the first demonstration of solar hydrogen production at a system level, according to Sophia Haussener, head of EPFL’s Renewable Energy Science and Engineering Laboratory. This means that unlike experimental devices in the lab, this prototype contains everything it needs to produce hydrogen continuously.

Hydrogen is a zero-carbon fuel and can be used as a battery to store renewable energy. The challenge is to be able to extract it profitably from underground or to produce it from renewable sources, in large quantities and at an acceptable cost.

Hydrogen is also among the major themes at the United Nations climate change conference in Dubai (COP28) from November 20-December 12. This article is part of a series exploring the potential and limitations of hydrogen and the role of science and industry in the search for the green fuel of the future.

The system called Arb, derived from the Latin word for tree, was patented by SoHHytec, an EPFL start-up, and promises to overcome two of the main problems hindering the development of green hydrogen: the high cost of producing and the difficulty of transporting what is considered the energy carrier of the future.

Arb can produce hydrogen close to its place of use and at a similar, if not lower, cost than so-called grey hydrogen, which is generated from methane and coal. Currently, 96% of the hydrogen produced in the world comes from fossil sources.

This has enabled SoHHytec to raise more than CHF3 million ($3.4 million) in funding. Above all, the start-up has been able to convince companies from the metallurgy, energy and logistics sectors, which rely on renewable hydrogen to reduce their CO2 emissions. After ten years of research and development, the “artificial tree” is ready to bear fruit.

How does the artificial tree that produces hydrogen work?

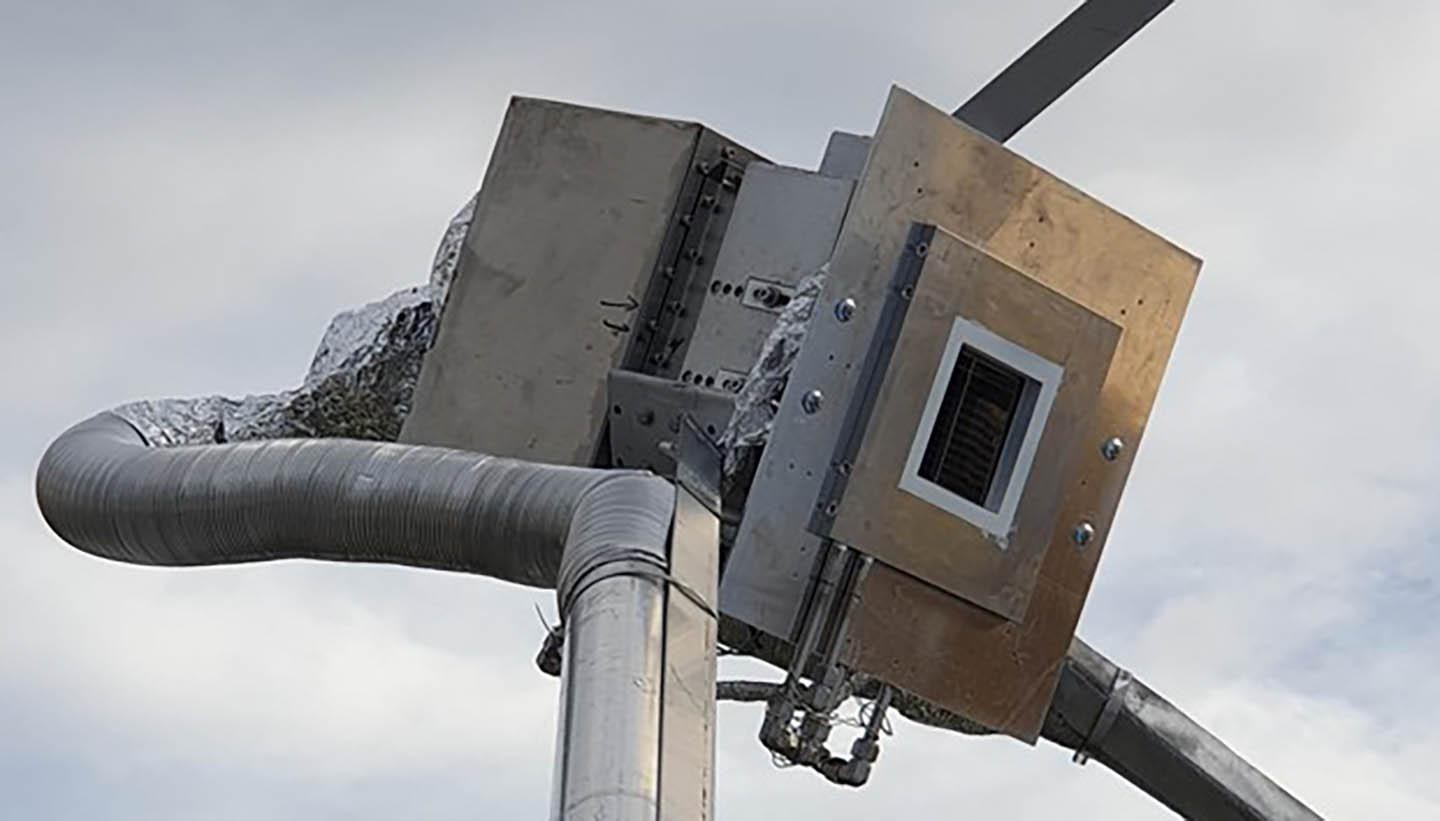

Sunlight is reflected from the parabolic mirror and concentrated in a reactor located at the focal point. In the reactor, the electric current generated by the sun splits water molecules (H2O) into hydrogen (H2) and oxygen (O2) – in a process similar to photosynthesis in trees and plants.

The system rotates on itself and follows the sun’s position in the sky to maximise output (see video below). It can produce hydrogen even in cloudy weather or at night by connecting to an external source of electricity.

What makes it unique is the ability to recover the heat and oxygen generated during the process. The heat could be used to heat buildings or certain industrial machinery, while the oxygen, often considered a waste product, could be used in hospitals to treat patients with respiratory failure.

SoHHytec claims Arb has a higher efficiency than conventional green hydrogen production plants, which run on solar or hydropower. Even taking into account heat and oxygen recovery, the efficiency approaches 80%, according to the start-up.

Enough to power one car a day, for now

The hydrogen can be tapped directly from the Arb system. It has a purity of more than 99% and is pre-compressed in the reactor, making it ready for use, says co-founder Saurabh Tembhurne. With a production of about half a kilogram of hydrogen per day, the prototype could power a fuel cell vehicle that travels about 70 kilometres.

The photochemical reaction for producing green hydrogen has been known for decades, but its practical implementation has faced challenges so far. The system developed at EPFL marks a significant step towards sustainable energy solutions, writes mechanical engineer Canan Acar from the University of Twente in the Netherlands in an email to SWI swissinfo.ch. She has been researching green hydrogen for more than 15 years. “Its localised production capacity, mitigating the need for extensive transportation logistics, further adds to its practicality and scalability,” she writes.

The lifespan of Arb is estimated at about 20 years, and to increase production, it is enough to either increase the diameter of the parabolic dish or multiply the number of “artificial trees”, as the following animation shows:

Kickoff for green hydrogen production at industrial companies

From February 2024, the first demonstration plant will be operated next to a metal construction plant in Aigle in southwestern Switzerland. The company Zwahlen & Mayr will install five 20-megawatt dishes with a diameter of nine metres – in other words, a small forest of Arbs. These will cover around 20% of its hydrogen needs to heat water, according to the company’s deputy director, Christian Charpin.

SoHHytec plans to export its innovation. There are plans for a park with a thousand Arbs in California that will produce up to 2,400 tonnes of hydrogen a year. Such plants can, for example, provide green fuel for heavy transport and power 150 trucks that travel 500km a day.

Saurabh Tembhurne believes that by using only concentrated sunlight, the price of producing green hydrogen in the United States could drop to about $2.50 (CHF2.20) per kg, a cost similar to that of grey hydrogen made from methane. (In Switzerland the price is currently CHF15-23 per kilo). If there were also hospitals in the vicinity that were prepared to buy the oxygen from the operators, as is planned for the Swiss metal company, the cost of hydrogen would fall even further.

SoHHytech is also in discussions with partners in India, including chemical producers and transportation companies that want to replace diesel in trucks and trains with hydrogen.

More

Once a hydrogen vehicle pioneer, Switzerland lags in the green fuel race

The need for the right climate

The success of these kinds of technologies is linked to the context in which they are deployed, Canan Acar notes. For example, the efficiency and feasibility of solar hydrogen systems are highly dependent on geographical and climatic conditions. “Regions with high solar irradiance will benefit most, but the viability may be limited in areas with less consistent sunlight,” she points out.

Existing industrial structures need to be technically adapted in order to integrate the Arb systems. This requires economic considerations and careful planning on the part of companies, Acar says.

SoHHytec is focusing on the industrial sector for now, offering companies to invest in its infrastructure or enter a long-term agreement to purchase hydrogen at a set price.

However, the start-up does not rule out the possibility of residential applications in the future. The use of hydrogen in residential settings is still uncommon and subject to strict local regulations, says Saurabh Tembhurne. “However, we could imagine smaller parabolic disks for single-family houses, with which people will produce energy and heat in their own backyard,” he says.

Edited by Sabrina Weiss

More

White hydrogen – Switzerland joins the scramble for ‘clean oil’

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.