Tiny technology takes on Gulf’s big oil problem

A high-tech product developed in Switzerland will be among the newest efforts used in the battle to contain the oil slick blanketing parts of the Gulf of Mexico.

HeiQ, a start-up based in central Switzerland, confirmed it has been in discussions with officials in the United States about its fleece that can separate oil from water.

President Barack Obama toured the shores of Mississippi and Alabama on Monday seeking to boost morale in the southern states.

The Swiss product was selected from some 20,000 proposals submitted to British petrol giant BP, which operated the Deepwater Horizon oil platform.

“At the moment the preparations are being made for the first live trials in the Gulf of Mexico,” Carlo Centonze, head of the Aargau-based firm, told swissinfo.ch. HeiQ is a spin-off of the Federal Institute of Technology in Zurich (ETH), one of the country’s two prestigious engineering universities.

A spokesman for TWE, the German company that produces the 500-metre-long, 5.5-metre-wide fleece, said it was on the way to the US.

Non-wovens

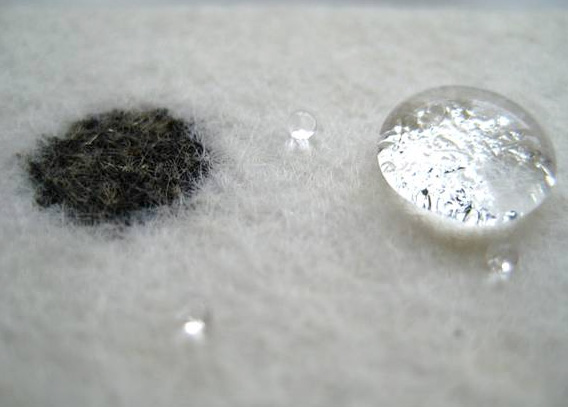

The project, “OilGuard”, utilises non-wovens, a family of materials that, after treated, attract oil but keep out water.

It will require a fair degree of logistical coordinating, experts say. “First we need the approval of US authorities for trials and secondly, we need the support of the National Guard to test the new material locally,” Centonze said.

The Deepwater Horizon exploded on April 20. It was owned by Transocean, a Texas-based company incorporated in Zug, Switzerland.

If the trials are successful, HeiQ and TWE say they can produce some 30 tons of the fabric – the equivalent of a shield around ten kilometres long. In the medium-term, they should be able to expand production to the equivalent of 300 kilometres of beachfront protection per day.

Big business?

The project could mean big business for HeiQ. Centronze calls it a development that could lead to the quick creation of new jobs in the high-tech sector but warns against over-exuberance. “We have no silver bullet but a solution to one part of the problem,” he said.

The technology could be employed at other beaches dependent on the tourism industry, said Alexander Hauri of Greenpeace Switzerland. Although BP has in the last two weeks seen some success in curbing the amount of oil flowing into the ocean, the Gulf of Mexico has nevertheless been polluted to the tune of some roughly 170 million litres of crude.

Independent experts warn of high-flying hopes. Theoretically the fleece can soak up around one-third of the oil in the Gulf. It cannot resolve the monumental challenges that plague the unique ecosystems in the Mississippi Delta, and the Gulf’s mangrove swamps, which are now a gooey brown.

Erwin Dettling, swissinfo.ch (Adapted from German by Justin Häne)

Non-wovens are a technology somewhere in between textiles, paper, felt, film and leather.

They combine the advantages of natural materials and the benefits of modern fibre chemistry.

The materials can be versatile: fireproof, light, conductive and thin.

HeiQ is a spin-off of the Federal Institute of Technology in Zurich (ETH).

The company, founded in 2005, specialises in the treatment of textiles.

It has 23 employees.

Over the past three years it has made a name for itself as a producer of anti-bacterial, odour-inhibiting silver-based materials for sportswear and hospitals.

That process was developed by Murray Height, a 30-year-old Australian chemist.

Carlo Centronze, 36, is an ETHZ engineer and head of HeiQ.

Previously he was involved with Myclimate, a climate change organisation, in canton Ticino.

Centronze sits on the board of Emanuele Centronze SA, Switzerland, a company founded by his father.

The company has for many years represented BP in Switzerland.

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.