‘Our biggest challenge is to meet the demand for sustainable fuels’

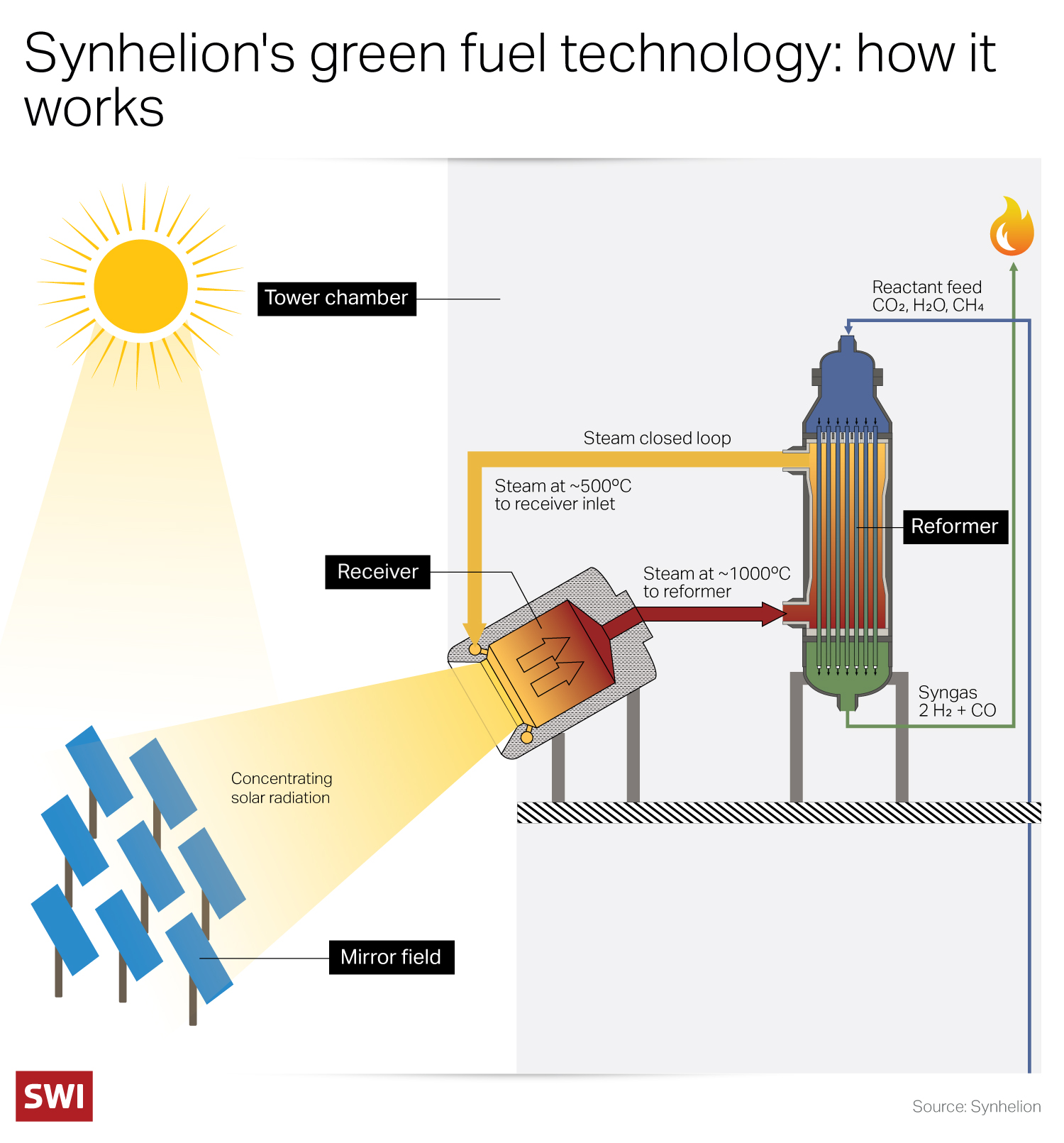

New regulations are pushing airline carriers to gradually ditch oil for cleaner fuels. Synhelion, a Swiss start-up, is turning sunlight into fuel, and seizing this opportunity to position itself in this emerging market segment.

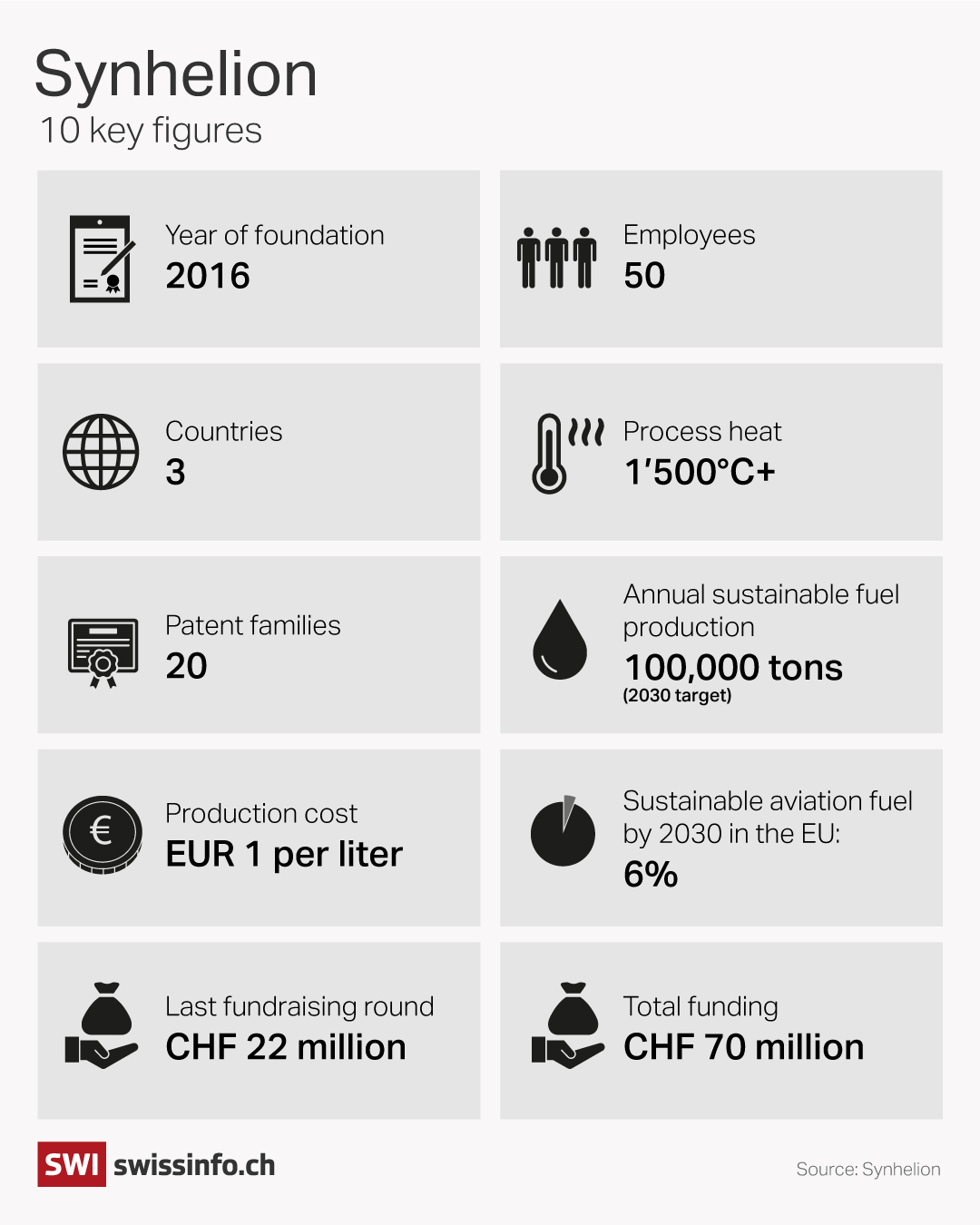

Synhelion stands out in the Swiss startup scene: not just because it is pioneering the conversion of sunlight into sustainable fuel, a crucial innovation for the energy transition, but also because it has already raised CHF70 million (about $80 million) from major strategic investors. In 2024, only two Swiss startups raised more than that.

Moreover, its chairman is not the typical young and trendy tech guru nor a financial investor. The startup is led by Hans Hess—one of Switzerland’s most seasoned business minds.

Hess, a mechanical engineer, has held chairmanship roles in major industrial companies such as Reichle & De-Massari, Burckhardt Compression, and Comet Group. He also served as CEO of Leica Geosystems, chairman of Swissmem (Switzerland’s leading association for technology and industrial companies), and vice-chairman of Economiesuisse (Switzerland’s umbrella organisation for business and industry).

SWI swissinfo.ch sat down with Hess for an exclusive interview at Synhelion’s headquarters in Zurich to discuss the challenge of raising capital in an increasingly unstable world.

SWI swissinfo.ch: At the age of 70, what motivates you to chair a start-up like Synhelion?

Hans Hess: In this final phase of my professional career, I want to pass my experience on to the next generation of business leaders. I have always been passionate about industry, technology, and business success, and I truly enjoy working with the dynamic young management team at Synhelion.

As a seed investor, I was actively looking for promising start-ups in the cleantech sector. After investing in Synhelion and collaborating with its management team for six months, the founders invited me to become chairman, a role I assumed in December 2020.

SWI: Are you also involved in attracting co-investors, customers, and partners for Synhelion?

As chairman, my primary focus is on strategy and governance, ensuring the right framework for success. However, I also leverage my network to attract co-investors and regularly engage with high-level policymakers, customers, and suppliers. In summary, I would describe myself as an active non-executive chairman, dedicating about 40% of my time to Synhelion.

SWI: Many start-ups spend years developing a technology without certainty about its commercial viability. Where is Synhelion in its development and will it be able to scale production to become sustainable financially?

In 2024, we resolved all fundamental technological challenges by successfully completing a demonstration solar fuel plant in Germany. In addition, our team has proven its ability to deliver complex projects on time, on budget, and to specification. We will soon begin constructing our first small commercial production plant in Spain, targeting solar fuel production in 2027. Larger plants will follow, with the goal of producing 100,000 tonnes of sustainable fuel annually by 2030.

More

The Swiss firm that wants to power planes with green jet fuel

I am confident in our ability to scale because we collaborate with experienced industrial partners. Most importantly, there is a significant market demand and we have already pre-sold most of the production volume of our future plant in Spain. The key remaining challenge is securing the necessary financial resources.

SWI: Why are you confident there is strong market demand for your sustainable fuel, particularly in aviation?

H.H: Regulations are driving decarbonisation and the energy transition, especially in the European Union, and increasingly in countries like Singapore, Brazil, and the United States. For instance, by 2030, airlines in the European Union must use a minimum of 6% share of sustainable fuel.

The aviation sector is our primary target because it lacks viable alternatives to reduce CO2 impact. Unlike electric vehicles, electric planes are impractical for long distances due to the weight of a battery. Another significant advantage of sustainable fuel is its compatibility with existing aircraft and fuel supply infrastructure, unlike electrification or hydrogen solutions.

SWI: Young companies often take longer than expected to bring products to market. Is this the case with Synhelion?

H.H: We lost about a year due to the Covid-19 pandemic, as some suppliers faced delivery bottlenecks. Currently, we are six months behind schedule compared to our original plan.

SWI: In 2022, the last time Synhelion spoke to SWI, your company was planning a production target of 875 million litres of fuel a year by 2030 – half of Switzerland’s annual aviation fuel needs. Are you on track to meet that goal?

H.H: I won’t comment at this point on capacity. But Synhelion remains committed to its ambitious yet realistic plans to scale-up production. We aim for a production capacity of 100,000 tonnes (or 125 million liters) of sustainable fuel per year in 2030.

SWI: You have already raised CHF70 million from international and Swiss investors such as the Swiss automobile trade group AMAG, Swiss International Airlines, Italian oil and gas conglomerate Eni, SMS Group specialised in industrial plants and Cemex which produces cement. How much more funding do you need until you become self-sufficient?

H.H: It depends. A large plant capable of producing 100,000 tonnes per year of sustainable fuel requires an investment of CHF1.5 billion. Ideally, a major oil and gas company would license our technology and fund such a plant, allowing Synhelion not to weigh itself with assets. However, we will likely need to continue to co-invest in companies until we can further demonstrate commercial viability and ensure big oil and gas players are on board.

SWI: Given the strong international focus on energy transition, was it challenging to raise funds for Synhelion?

H.H: Our initial fund raising was relatively easy. However, since 2023, global investment in ventures like ours has declined significantly, making fundraising more challenging. The slowdown in cleantech investment is due to higher interest rates globally and economic, political and regulatory uncertainties. Capital-intensive cleantech projects face longer payback periods, making them more challenging in such an environment.

SWI: Part of the criticism for sustainable fuel is that it impacts land use, that it keeps a polluting industry alive and it can attract subsidies that could mitigate climate change elsewhere and get in the way of global emission-reduction goals. Do your technological solutions achieve significant CO2 reductions across the entire value chain?

H.H: Absolutely, and this is a crucial point. Our process requires three key ingredients: solar energy, water, and sources of carbon (CO2). For the latter, we use biowaste from agriculture. As a result, our plants must be located in areas with abundant sunlight and water, near agricultural land but without competing for farmland. Of course, we will need to transport our sustainable fuel from production sites to airports; however, as the fuel has a high energy density, this is not a significant issue and we can use the existing downstream infrastructure of the oil and gas industry.

More

How sustainable fuels created from thin air could solve the energy crisis

For full-scale plants, we seek “marginal land”— areas that meet our requirements without displacing agriculture. Such locations are rare in Europe, and even more so in Switzerland, but they are plentiful and widely distributed worldwide. We are considering Morocco, where all factors align to achieve an estimated 85% CO2 reduction. Importantly, we can precisely quantify this reduction, distinguishing us from many greenwashing initiatives.

SWI: How do you protect your innovations, given that several of your academic partners (ETHZExternal link, EMPAExternal link, SUPSIExternal link, etc.) own some of your critical patents?

H.H: Intellectual property protection is a top priority, as we intend to license our technology in the future. As a spin-off, we use certain patents of the Swiss Federal Institute of Technology ETH Zurich but have secured exclusive licensing rights. Additionally, we own 20 patent families and possess significant know-how in the heads and hands of our 50 employees. We recognise that patent protection is never foolproof, so speedy and continuous innovation remains essential.

SWI: Why do you primarily collaborate with foreign industrial partners but work with Swiss clients such as Pilatus, SWISS, Lake Lucerne Navigation, Zurich Airport, and AMAG Group on pilot projects?

H.H: From the outset, we sought global industrial leaders to facilitate scaling. However, pilot projects require close collaboration so Swiss companies are a natural choice to start with. Some Swiss partners, such as SWISS and AMAG, also provide access to international companies like the Lufthansa or Volkswagen groups.

SWI: Who are your main competitors?

H.H: Rather than competition, our biggest concern is meeting demand. Regulatory requirements will create a significant supply gap for sustainable fuels. The primary competing technology is HEFA (Hydrotreated Esters and Fatty Acids), which refines vegetable oils, waste oils, or fats into sustainable fuel. HEFA is commercially established, with plants producing 100,000 tonnes annually. However, its feedstock is limited, and a production cap will soon be reached. Next-generation sustainable fuels such as our solar fuels are therefore needed.

SWI: Your first two plants are in Germany and Spain. Did EU subsidies influence this decision?

H.H: No. We did not receive EU subsidies. We chose Germany for our pilot plant because we could leverage the infrastructure of the German Aerospace CenterExternal link, with strong local support. Spain was selected for our first commercial plant due to its available “marginal land” and sunny conditions.

SWI: Will your sustainable fuel be cheaper than fossil fuels?

H.H: No, but it will be competitive among sustainable alternatives. At full scale, we aim for a production cost of approximately €1 per litre—twice that of fossil fuels. However, we must transition to sustainable fuels to meet the Paris Agreement goals. As mentioned earlier, from 2030 at least 6% of aviation fuel in the European Union will have to be sustainable, but this small percentage will result in a minimal overall cost increase.

Hans Hess was interviewed before the inauguration of US president Donald Trump who has since then scaled back investment in clean energy projects.

Edited by Virginie Mangin/ac

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

You can find an overview of ongoing debates with our journalists here . Please join us!

If you want to start a conversation about a topic raised in this article or want to report factual errors, email us at english@swissinfo.ch.