Swiss robotics moves from research to delivering products

In one of the many laboratories at the Swiss Federal Institute of Technology Lausanne (EPFL), the robots of tomorrow – supple, agile, collaborative and intelligent – are coming into the world. SWI swissinfo.ch looks at the driving forces behind this flourishing research field and the start-ups it is spawning.

On the first floor of a futuristic-looking building on the EPFL campus, Aude Billard and her team are writing new software for existing robots to improve their capabilities. In this laboratory, humans and robots co-exist – and the gap between them is narrowing.

Over the course of the last decade, Switzerland has become a world leader in the robotics field thanks to work by artificial intelligence (AI) pioneers like Billard.

“If you take the top 20 labs in the world, almost a quarter of them are in Switzerland, despite the fact that we only have eight million inhabitants,” says Billard, who heads the algorithms and learning systems laboratory (LASAExternal link) at the EPFL.

The robotics industry has long been dominated by manufacturing centres like Korea, China, Germany and the United States. But Switzerland’s strength lies in research and start-ups, especially when it comes to new materials, programming and AI.

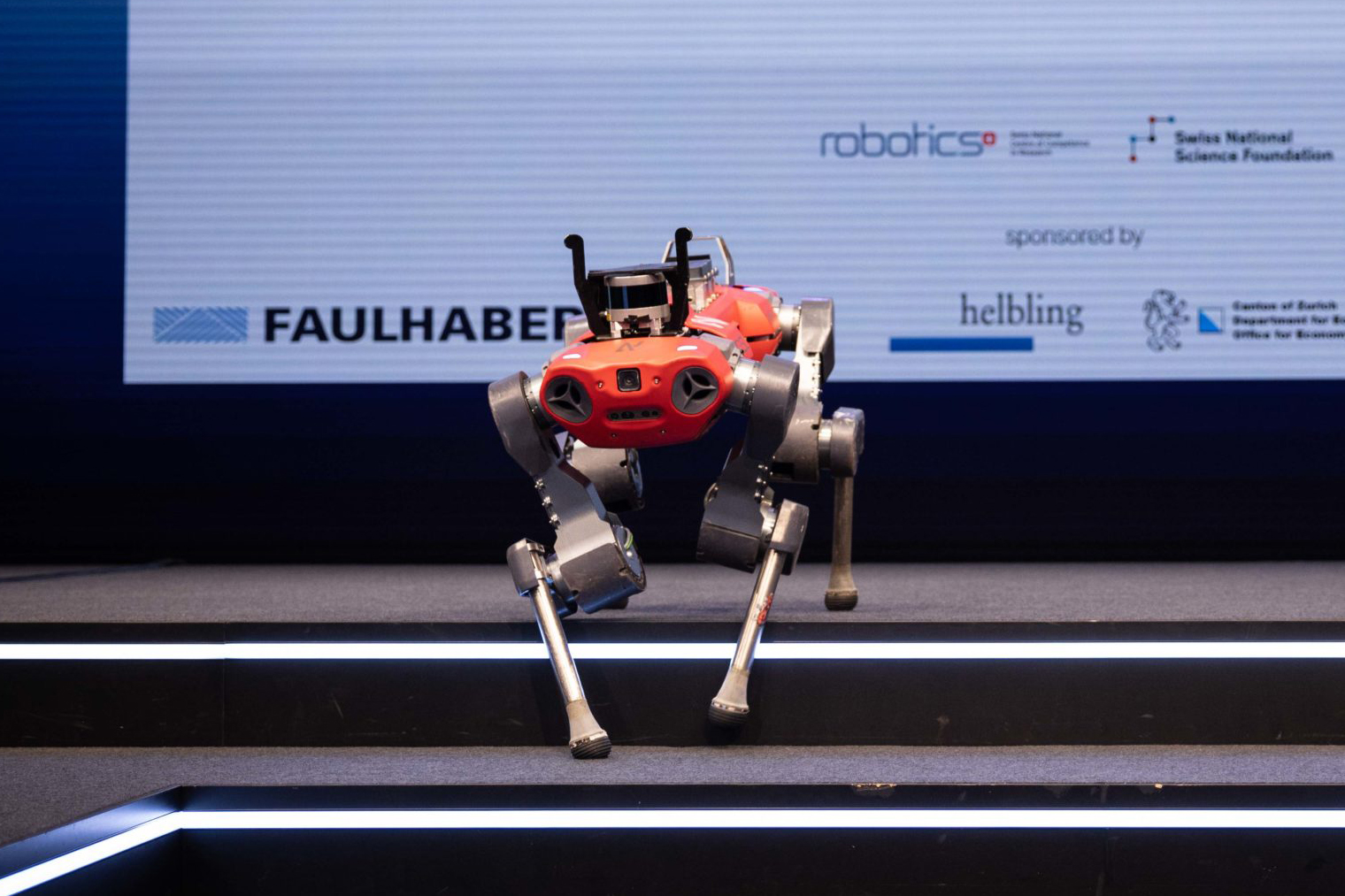

In 2010 the Swiss National Science Foundation (SNSFExternal link), a public organisation that supports research, launched the National Centre of Competence in Research (NCCR) RoboticsExternal link, which groups six schools and technical institutes under the direction of the EPFL.

From laboratory to factory

Twelve years and CHF85 million ($90 million) later, things are moving to the next stage. The Swiss Innovation Agency (Innosuisse) has launched an NTN Innovation BoosterExternal link for Robotics, providing it with CHF500,000 in annual funding and to be headed by Billard. Innovation Boosters are designed to promote knowledge transfer and encourage collaboration.

Up until now the Swiss have been focused on cutting-edge research. Their attention is now turning to fulfilling the growing market demand for robots of all types.

“We are going to support at least ten projects a year and also help newcomers to the field to obtain more generous financing,” explains Billard. “Creating a start-up is one thing, but to deliver a real product is another.”

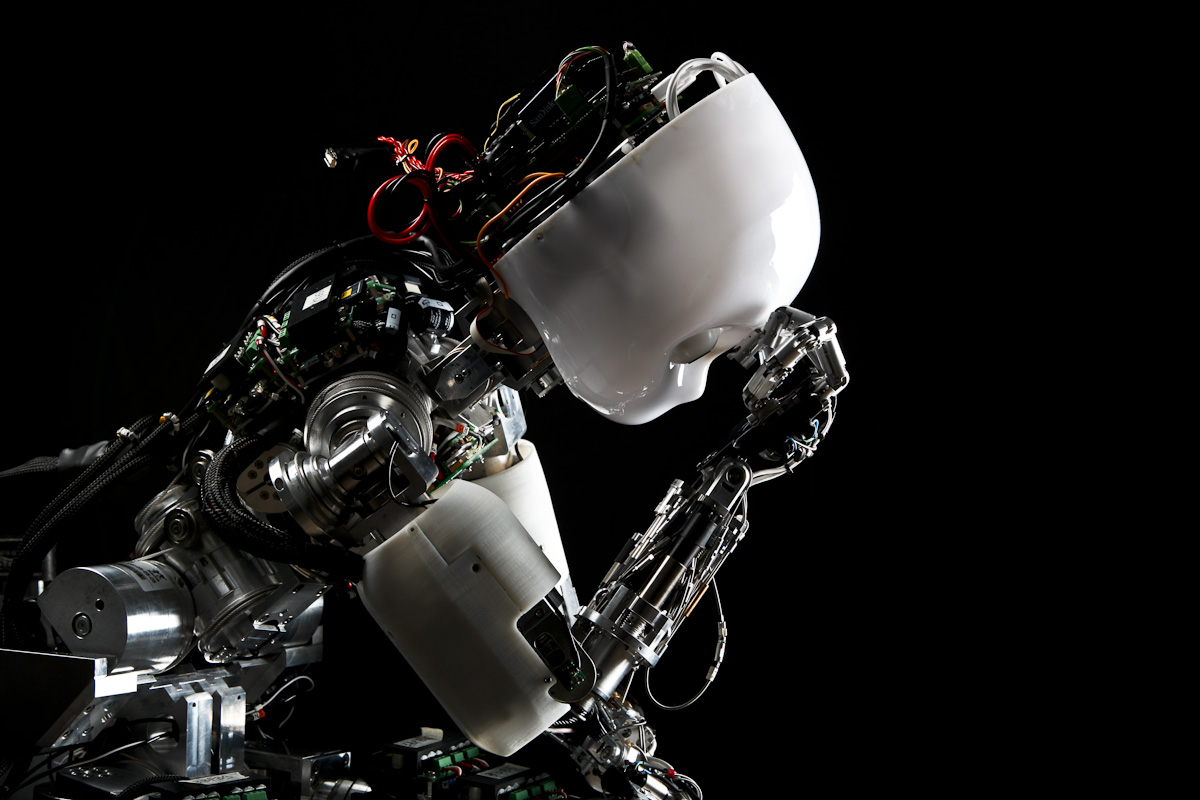

One of the challenges for robotics is to move from rigid structures made of metal or hard plastic to more flexible materials. Only the hand of a “soft robot” can come close to the gentleness and efficacy of the human hand. It’s a matter that goes beyond sheer comfort – robots have to be able to interact with the surrounding environment and people.

“There’s been a lot of advances in research,” says Billard. “In some areas it could even lead to [the creation of] industrial products.”

“I think we’re going to see a lot of great achievements,” she adds.

Flexible materials, however, pose all kinds of new problems related to control and precision, especially when it comes to gripping objects. The challenge, for example, is to teach a machine how to pick up a carton of milk without crushing or dropping it.

“As soon as we have these soft materials, it becomes very non-linear, and there is a lot of uncertainty in terms of measurements,” says Billard. “So we need to develop algorithms that control this, and that includes AI. But I think robotics will get to a point where it is possible [to do this].”

>> A robotic arm controlled directly by the human brain: this is one LASA project

Medicine and ethics

Switzerland also excels in the area of medical robotics, which constitutes a large part of the research done at the NCCR. The scope is vast, encompassing everything from surgical robots to micro-robots that are implanted in the human body, to active prostheses or exoskeletons that support rehabilitation or give autonomy back to people with reduced mobility.

The new Innovation Booster for Robotics will also be open to areas that are not strictly technical. The development of robots raises ethical and legal questions that Billard says are “absolutely essential”.

“We will be attentive to it and if we have good proposals, we will support them.”

Programming for everyone

Back at LASA, Billard’s team have not waited for the launch of the Innovation Booster to develop the fruits of the lab’s research. Three start-ups have already been founded. They include AICA, created in 2019 and focused on simplifying robotics programming used in industry or small businesses to make it accessible to everyone.

“When you buy a robot, programming is at least as expensive as the machine itself,” says Baptiste Busch, co-founder of AICA. Having studied at the technical institutes of Nantes, Bordeaux and Warsaw, Busch has a doctorate in robotics and arrived on the shores of Lake Geneva as part of a European project.

“We had quite a few manufacturers who approached LASA to apply the solutions that we were developing to their machines,” he says. “But that’s not something the lab is set up to do.” So together with Billard, he decided to go the start-up route.

>> This AICA presentation video promises to make using a robot as easy as using a mobile phone

AICA began life as a consulting firm but quickly moved to working with robotics integrators – companies that create the link between the manufacturer and the user.

“We offer software solutions that allow them to change the way they program the robots – solutions that are less rigid than they are right now and which are developed through our own research,” says Busch.

AICA supplies an interface that enables the client to reprogram a robot themselves when they want to assign it a new task – all through an intuitive method that doesn’t require the person to have an engineering degree. Thanks to algorithms that are constantly learning, the person can also teach the machine the new task, no reprogramming necessary.

It’s a way for working robots to help just about anyone, from big businesses to small ones.

In addition to her work at the EPFL, Aude Billard is also a Lausanne city councillor with the Social Democratic Party.

“Let’s be honest – I don’t really believe in sustainable robots,” she says. “On the other hand, we can ensure energy efficiency by using robots only when it’s necessary.”

“It’s like with cars,” she adds. “We’ll always need them, if only for firefighters and ambulances, but we should also ask ourselves what they’re costing society in general.”

Robots, after all, need batteries that are charged with electricity that itself may not have been produced sustainably.

“You can question the utility of a robotic dog versus a real dog,” says Billard. “But if we’re talking about an automated wheelchair versus a mechanical one, I think society will lean towards the solution that gives the person greater mobility, greater autonomy and a better quality of life.”

(Adapted from French by Sophie Douez/Geraldine Wong Sak Hoi)

More

Robotic innovations that will change our lives

In compliance with the JTI standards

More: SWI swissinfo.ch certified by the Journalism Trust Initiative

Join the conversation!